ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreFeatures & Specs

- Eliminates dull, repetitive tasks normally performed by a human operator

- Increases food safety and reducing product contamination by minimizing human contact

- Delivers labor savings; strong return on investment

- Runs a variety of products with minimal (if any) changeover

- Provides easy access to all components for cleaning

- Is easy to maintain; minimal wear parts

The Flexible Robotic Loading System is a versatile picking system that can load, orientate, stack and group products into thermoformed trays. Its robotic picking system can grip hard-to-handle products, such as poultry and meats, as well as virtually any other product shape.

Quest Industrial’s raw and packaged robotic cheese stick pick and place system is clean, quick and nimble. Odd word to use right? We don’t think so. Our robotic cheese stick pick and place system is just that, quick and light in movement. We are able to get these robots picking & placing so accurately and fast that it would seem like the cheese is floating. Some of our customers have said that these robots move so fast that they can hardly watch to keep track of how fast the robot is actually moving.

This robotic cheese stick pick and place system is perfect for applications which need high rates, a long reach and have a small payload. Our robotic experts use FANUC’s M430 that has a payload of up to about 4lbs with a reach of 35 inches or FANUC’s LR Mate which has a payload of up to 15lbs and a reach of about 28 inches. Depending on the weight of your product, our robotic cheese stick pick and place system can reach rates of up to 600 pieces per minute!

Robotic Cheese Stick Pick and Place System Highlights

- Compact and fast automated picking & packing robotic cell

- Product in-feed rates from 60 to 600 pieces/minute

- Reconfiguration with the press of a button

- Ability to accept a wide range of product types, sizes and textures

- Custom orientation of product to meet your needs

Standard Configurations for the Robotic Cheese Stick Pick and Place System

- State-of-the-art safety features used

- Automated visual verification of picking tools and placement

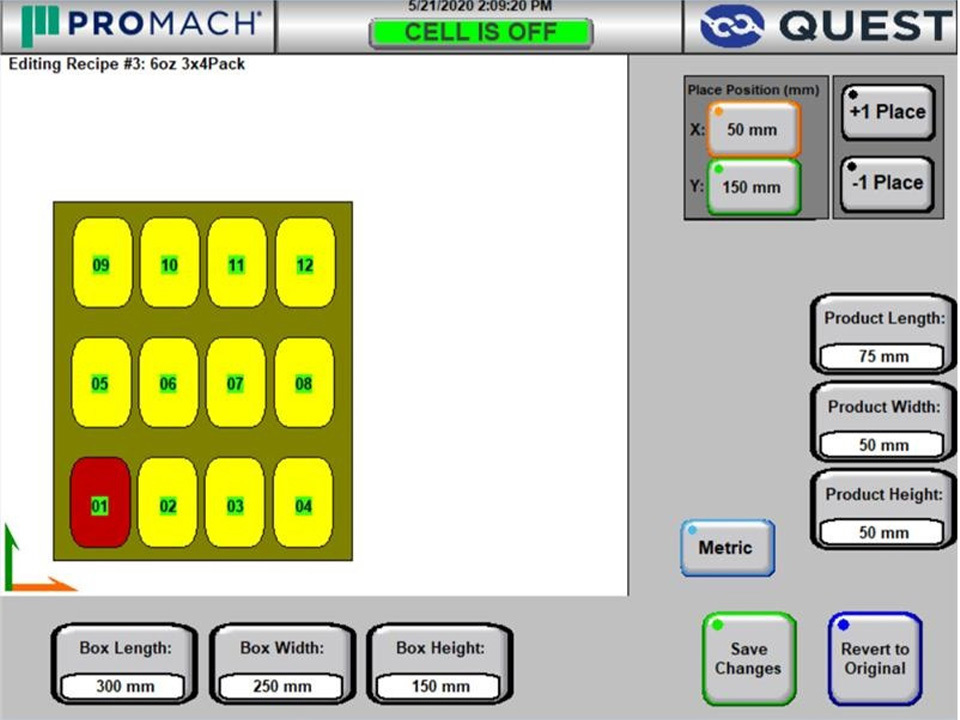

- Touch screen operator interface that makes diagnostics easy

- Operators manual and mechanical documentation at your fingertips

Robotic Cheese Stick Pick And Place System Optimization

- Pick & Place single or multiple products and/or product types

- Customized robotic placement for your needs

- Customized robotic end of arm tooling for your needs

- Customized conveyor size and placement

- Automated visual inspection & rejection

- Product weight verification

Specifications of the Robotic Cheese Stick Pick and Place System

Capacity

Many capacity configurations available for your product weights from oz to 4 lbs

Construction

- 316 stainless steel steel formed and welded construction for washdown environments and direct raw food contact

- Mild steel or 304 stainless formed and welded construction for incidental contact with water and a high-moisture environment for packaged cheese stick pick and place

- Components have been selected with moisture considerations and sanitation in mind to minimize deterioration and maximize component service life

Dimensions

Base machine size

- Single Robot Cheese Stick Pick & Place 5’x6′

- Double Robot Cheese Stick Pick & Place 8’x7′

Speed of the Robotic Cheese Stick Pick & Place System

Many different configurations with speeds from 60 to 600 pcs/min

Finish

- Raw Stainless

- FDA-compliant plastics

- Built to 3A guidelines

Controls

Fanuc Robotics with Allen-Bradley – consisting of PLC, touch-screen HMI, safety systems and sensors

Ease of Maintenance

Our machines are open and have full sensor and diagnostic features that come standard on the HMI

Product Management

Vision and weight systems are available for integration into the system to output data values of target weight/size, verified weight/size and/or gross weight/size.

The Quest Robotic Spider Pick & Place is one of the fastest pick and place product lines offered. If you are looking for a robotic cell that has high rates with a lower weight capacity, this is one of the best options in the market. Quest Industrial’s Engineers have worked to develop various styles of tooling, whether it be for direct food contact or packaged product, there is a solution for you. Our Robotic Programming Engineers work to make sure that every move is the most efficient and quickest option for your needs.

Robotic Spider Pick & Place Highlights

- Quick and compact automated picking & placing robotic cell

- Product in-feed rates up to 1000 pieces/minute

- Accepts a wide range of product types, sizes and textures from cups to shreds and rolls to viles

- Custom orientation of product to meet your needs

- Pile stacks

- Base Stacks

- Random Cuts

- Shingle Stack

- 2-3 Stack

- Twin Stack

Standard Configurations for Robotic Spider Pick & Place

- State-of-the-art light curtain safety features used

- Automated visual verification of packing tools and placement

- Touch screen operator interface making diagnostics easy

- Operators manual and mechanical documentation at your fingertip

Optimization for the Robotic Spider Pick & Place

- Pick & Place single or multiple products and or product types

- Customized robotic placement for your needs

- Customized robotic end of arm tooling for your needs

- Customized conveyor size and placement

- Automated visual inspection

- Product weight verification

Robotic Spider Pick & Place Specifications

Capacity

Many available capacity configurations for your product weights from 1/2 oz. to 20 lbs.

Construction

- Mild Steel or 304 Stainless Steel formed and welded construction

- Constructed for incidental contact with water and a high-moisture environment

- Components have been selected with moisture considerations and sanitation in mind to minimize deterioration and maximize component service life

Dimensions

Varies based on the user’s customization of cell, placement and size of enclosures and conveyors

Finish

- Raw Stainless, polished, matte and powder coated finishes available

- FDA-compliant plastics

- Aluminum

- Cast metals finished with corrosion-resistant coatings

Weight Management

Case weight systems are available for integration into the conveyor system to output data values of target weight, verified weight and /or gross weight.

Speed

Many different configurations with speeds up to 1000 pieces/minute

Controls

Fanuc Robotics with Allen-Bradley – consisting of PLC, touch-screen HMI, safety systems and sensors

Ease of Maintenance

Our machines are open and have full sensor and diagnostic features that come standard on the HMI

Rotary Vacuum Sealer Robotic Loader

Quest Industrial’s Robotic Loader of Rotary Vacuum Sealer is a robotic cheese loader is capable of working alongside preexisting equipment such as your Cryovac or Multivac equipment to pick and place your product into the sealing equipment applications.

Highlights

- Capabilities to accept many different product:

- Types

- Sizes

- Shapes

- Weights

- The robotic loader system is USDA & FDA approved for direct food contact

- Largest work envelope with the smallest footprint

Specifications of the Rotary Vacuum Sealer Robotic Loader

Capacity

Many available capacity configurations for your product weights from 0.1 lbs all the way up to 60 lbs

Speed

Many different configurations with speeds up to 36 Pieces/Minute

Let the Rotary Vacuum Sealer Robotic Cheese Loader do the repetitive

work that can cause work injury claims, while completing the tasks with

precision and speed. Be it cheese, butter, meat, or produce, the robotic

loader has the performance, reliability and efficiency to make you more

profitable and competitive.

Quests' Quik Pick QP100s are ideal for a number of industries including: