ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePrimary Packaging Machinery

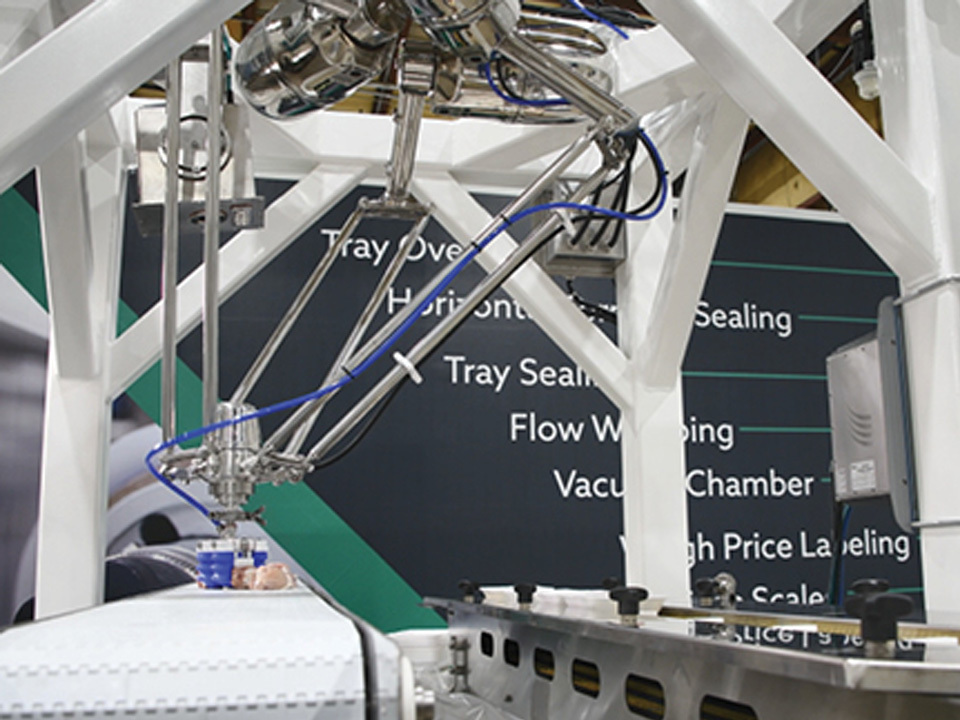

Quest offers primary packaging solutions that adhere to rigorous sanitary standards to closely protect retail and consumer products.

We understand 3-A, USDA, & FDA compliance and encompass those regulations within the equipment to help your facility pass safety and quality standards. Our engineers understand the unique environmental conditions required to package primary products, so our solutions use materials designed for durability and easy sanitation practices and are designed for wash down environments.

Quest has proprietary and specialized solutions that enable robotic automation in the rigorous environments where primary packaging operations take place, including:

The Quest Quik Pick QP100 is a family of pick and place solutions for direct food handling.

The Quest Quik Fill QF100 series are a family of solutions designed to automate the filling of single/multi-compartment trays, bowls, and clam shell containers.

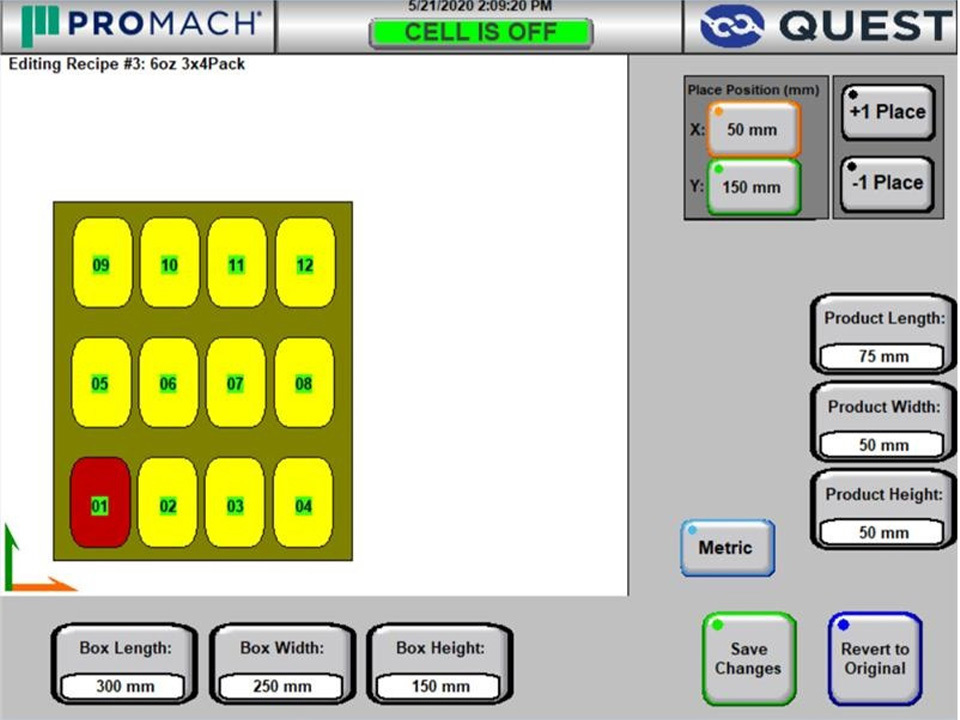

QPick is a dynamic primary handling software that allows authorized users to create pattern variations or entirely new ones.

QFill is a dynamic primary packaging software designed for the creation of personalized tray filling patterns.

Quest Qleen Coat Robotic Coating is our own proprietary robotic coating.